Steel Belt Conveyor Systems

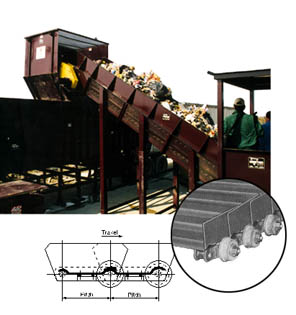

SA Class Steel Apron Belt Conveyors

Style A1 Heavy Duty Steel Apron Belt. The shallow double beaded pans are recommended for heavy duty continuous service, high impact loading such as MSW or for handling abrasive materials.

A superior, 3/8″ or 1/2″ pan belt for extreme service up to 8 ft wide. SA conveyors are used for high volume (20 to 50 tons/hour), heavy-duty applications such as feeding MSW into Mark-Costello’s TS-2000 Transfer System compactor, large Two-Ram scrap balers, C&D lines, and mixed waste lines.

Features Include:

- Beaded pan with 6″, 9″ or 12″ pitch engineered chain

- 10 to 25 hp motors

- Tapered roller bearings

- Pit covers

- Variable speed controls

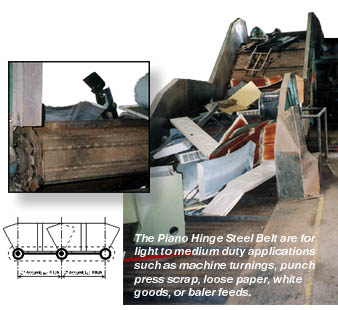

SE Class Economy Steelbelt Conveyors

A competitively priced equivalent to other piano hinged belts up to 7 ft. wide. SE conveyors can be used for high volume (12 to 30 tons/hour), heavy-duty applications such as precrusher compactor feeds, large Two-Ram scrap balers, and mixed waste lines.

Features Include:

- Piano hinged steel belt with 6″ pitch chain

- 7.5 to 20 hp motors

- Tapered roller bearings

- Pit covers

- Variable speed controls

Steelbelt Conveyors

| Product Class | Application | Width up to: | Shaft Elev. | Pit Length |

| SE | High volume (12 to 30 tph) Variable Speed Control (VS) standard |

7 ft. | up to 18 ft. | up to 100 ft. |

| SA | High volume (20 to 50 tph) Variable Speed Control (VS) standard |

8 ft. | up to 18 ft. | up to 100 ft. |