Dual Recycling Compactor

Compaction combinations are limitless with the DRC…

Garbage/Corrugated Corrugated/High Grade Paper Paper/Aluminum Cans

The DRC is excellent for…

- Hospitals

- Restaurants

- Manufacturing Plants

- Malls

- Retail Stores

- High Rise Office Buildings

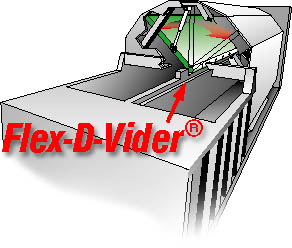

Flex-D-Vider® Creates Two Variable Capacity Compartments

Mark-Costello’s Dual Recycling Compactor, the DRC II, has a total capacity of 28 cubic yards. The two variable capacity compartments are separated by a 24″ high solid welded barrier. This wall prevents liquid leaking from one side to the other.

The DRC II accepts and compacts unequal and unpredictable volumes of two separate discardables. This is made possible by Mark-Costello’s patented Flex-D-ViderTM.

The Flex-D-ViderTM is a pivoting steel wall that adjusts the compartments’ capacity during the loading and packing process. For easier discharge of the materials in the smaller compartment, a hydraulic cylinder allows the operator to move the Flex-D-ViderTM to the vertical center of the container, relieving the pressure on the remaining waste or recyclables. Each compartment when loaded can represent as little as 30% (8.4 cubic yards) or as much as 70% (19.6 cubic yards) of the unit’s total volume. The DRC II can also be chute fed to increase customer security and reduce labor costs!

DRC’s Features & Benefits:

- Increase Your Return on the Sales of Recycled Products…

- Two separate compartments segregate waste and recyclables which increases your return on the sales of recycled products.

- Two Compactors in One…

- Separate, compact and process two different materials such as recyclables and garbage at the same time in an area where space permits only one compactor.

- Neat and Attractive Appearance…

- Both recyclables and garbage are neatly contained after compaction providing your building, facility, mall or store a neat and attractive appearance.

- Four Individual Doors for Controlled Discharge of Compacted Material

- Due to the many variable positions in which the Flex-D-ViderTM can be located, four individual doors are utilized for the discharge of materials.

- Upper Doors are top hinged and have ratchet locks allowing the door to be opened independently of the lower doors.

- Lower Doors are hinged in the center of the container. Each door is equipped with Mark-Costello’s standard ratchet latch and opens independently.

- For wet waste applications, an optional door gasket is available with Mark-Costello’s custom designed “P” Seal, developed expressly for wet waste unitized compactor/containers. Either or both sides may be gasketed.

- Quik Clean TankTM…

- The Quik Clean TankTM with exclusive Trash CheckTM is a standard feature on the DRC II. It funnels any liquid seepage which occurs during compaction into an enclosed area underneath the charge box floor. The liquid is automatically discharged at the disposal site in effect flushing the container and the area behind the ram.

- Easy and fast installation! Installation costs are cut by half over conventional compaction systems.

- Fire hose connection provided on each unit.

- Factory testing to assure leakproof construction.

All of Mark-Costello’s RamJet 225 Series Compactors are Totally UL Listed!

Structural Dimensions

The DRC II uses a Remote Power Pack that remains on-site while the self-contained compactor container is taken to the landfill or recycling center.

| Charge Box Capacity | ||

| [Mfrs. Rating – each side] [Mfrs. Rating – total] |

0.91 cu yd 1.82 cu yd |

0.70 m3 1.40 m3 |

| [WASTEC Rating – total] | 1.79 cu yd | 1.37 m3 |

| Clear Top Opening | 34 1/2″L x 48″W | 876mm x 1219mm |

| Capacity per hour | 165 cu yd | 126 m3 |

| Performance Data | ||

| Cycle Time | 39 seconds | 39 seconds |

| Total Normal Force | 31,800 lb | 141 kN |

| Normal Ram Face Pressure | 18.7 psi | 129 kPa |

| Ram Penetration | 6 1/2″ | 165 mm |

| Electrical Equipment | ||

| Electric Motor 3/60/230-460 | 10 hp | 7.5 kW |

| Electric Control Voltage | 120 VAC | 120 VAC |

| Panel Box Assembly | ||

| UL Rated Key Operated | ||

| All Circuits Fused – 3 Push Button Station Start/Stop/Reverse | ||

| Hydraulic Equipment | ||

| Hydraulic Pump | 10 gpm | 38 L/min |

| Normal Pressure | 2000 psi | 138 bar |

| Cylinder Bore | 4 1/2″ each | 114 mm |

| Cylinder Rod | 2-1/2″ each | 64 mm |

| Cylinder Stroke | 55-1/4″ each | 1403 mm |

| Weight | 16,000 lbs. | 7258 kg |

Pictures on this page are illustrative only. Specifications are subject to change without notice to accommodate improvements to the equipment. Certified in compliance with ANSI Regulation Z245.2, all OSHA standards, and certified under WASTEC’s Stationary Compactor Certification Program. Products must be used with safe practice and in accordance with said regulations and standards.

This DRC application features a TrashMinder monitor system. Note the two separate doghouse doors – one for trash and the other for recyclable cardboard.

Optional Features Available

The Dual Recycling Compactor can be fitted with a variety of optional equipment such as thru-the-wall security chutes and lockable doghouse hoppers. The DRC is well suited for ground, doghouse, dock or chute feed applications. Doghouses may be rear or side feed, or both (as shown at right).

The DRC II can be fitted with a various configurations of cart dumper systems. Other options include: multi-cycle timer, dual controls, ozone odor control system, security chutes, hoppers, and many much more.

The optional TrashMinder® is the most advanced method for reporting and measuring container fullness as well as for managing user access and billing. Click Here for details.